Detail Information

Description :

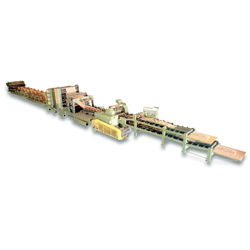

Stepped-end, economy-end-cut, multi-wall pp paper bag making machine:

Printing unit:

1. The unit uses water-base inks could print up to three colors.

2. The Printing Plate is a 7 mm rubber plate attached to 1 mm canvas (8 mm thick totally), which is attached to the aluminum printing cylinder and can be replaced easily. (The thickness of plate could be up to customer request).

3. Printing length is variable in every 1/2" step.

4. While machine is running, could do 360° degree back and forward leaf and right precision adjustment to match each color together.

5. When the main driver stops, printing cylinders are lifed automatically and the inking unit started (through independent motors).

6. Ink circulation system is available.

Cross pasting unit:

Designed to glue tube web laterally.

Gule unit:

Use glue pump to circulate glue and apply glue to side seam.

Could attach a pin hole punch equipment, could be fix position punch or whole bag punch, to improve breath of bag.

Forming unit:

Could from flat or gusset bag. Bag width could be adjustable in 340 mm-632 mm range.

Perforating unit:

Designed to perforate each web for making stepped-cut tube.

Cutting unit:

This unit is for cut tube length, every 1/2" have one size, cutting parts is a teech type knife (have straight cut and economical cut type), also could cut by push equipment an automatic counter, let you know production quntity for every days or every minutes.

Delivery unit:

This unit is when bag after fromed and cut delivery to position for stack equipment with automatic counter, could be set up 20 bags for one stack, after gather 20 bags, will move to stacker for worker's convenient.

Specification :

Technical details 1. Speed: max. 250 tubes/min. 2. Type of tube: as shown below. 3. Tube length (cl): 20"-50" (508-1270mm). 4. Tube width (w) (flat tube): 16 1/2"-25" (420-635mm). 5. Tube width (w) (gusset tube): 12 1/2-25" (340-635mm). 6. Gusset width (gw): 3"-8" (76-203mm). 7. No. Of ply: upto 6. 8. Paper roll width: max. 59" (1500mm). 9. Paper roll dia: max. 50" (1270mm). 10. No. Pf printing colors: 3 colors, at your option. 11. Motor total hp: 47hp heater 9kw. 12. Net weight: approx. 30 tons (3-color type). 13. Gross weight: approx. 34 tons (3-color type). 14. Measurements: approx. 395cu meters (3-color type). 15. Container: 40 foot 2 units, 20 foot 1 unit.

Related Prodcuts

CS Machinery Co., Ltd.

- Taiwan